The Weber DCOE is a side-draft carburetor, meaning the air and fuel mixture enters the engine from the side, rather than from the top like on a traditional downdraft carburetor. This design is favored in performance applications, thanks to its improved airflow and reduced restriction.

Venturi: The venturi is a specially shaped restriction in the carburetor's bore. As air flows through the venturi, its velocity increases, creating a low-pressure area. This low pressure draws fuel into the airstream.

Main Jet: The main jet controls the amount of fuel that is drawn into the airstream at higher engine speeds. It is located in the fuel circuit after the venturi.

Emulsion Tube: The emulsion tube mixes fuel and air before it enters the venturi. It is located in the fuel circuit ahead of the main jet.

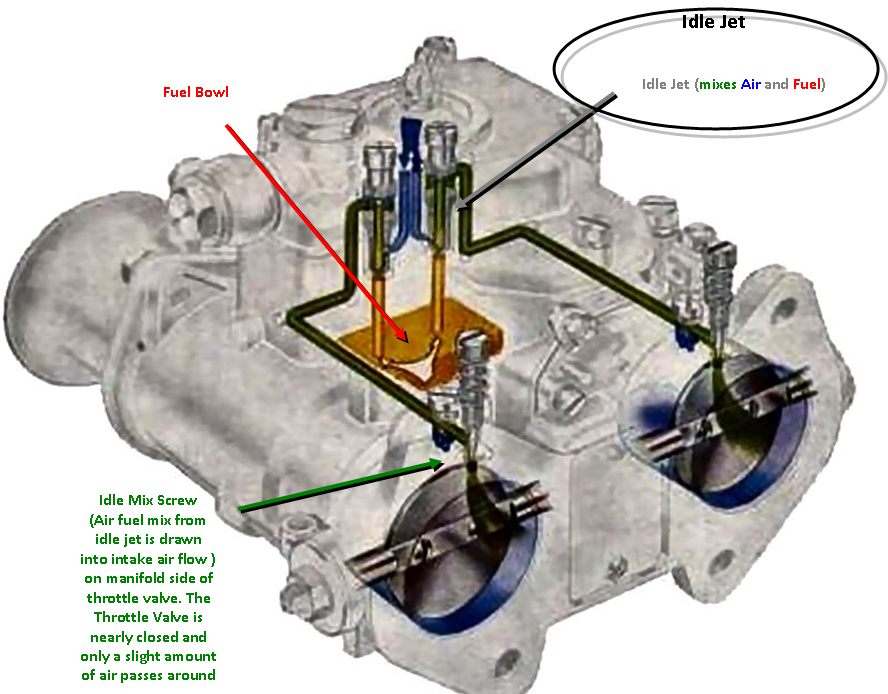

Idle Jet (Circuit): The idle jet provides the correct air/fuel mixture, bypassing the throttle valve, for idle and low-speed operation when throttle valve, or blades, are closed or almost closed. It consists of an idle jet and an idle mixture screw.

Accelerator Pump: The accelerator pump (along with the pump jets) provides an extra shot of fuel when the throttle is opened quickly, preventing a lean condition and hesitation.

Fuel Bowl / Float Bowl: The float bowl maintains a constant level of fuel in the carburetor. It contains a float that rises and falls with the fuel level, controlling the fuel inlet valve. (See Idle Jet image above for a different view)

Operation:

- Air enters the carburetor through the air cleaner and flows through the venturi.

- The increased air velocity in the venturi creates a low-pressure area that draws fuel from the float bowl through the main jet and into the airstream (#7 above).

- The air and fuel mixture is then drawn into the engine's cylinders.

- At idle and low speeds, the idle circuit provides the necessary air/fuel mixture.

- When the throttle is opened quickly, the accelerator pump injects an extra shot of fuel to prevent a lean condition.

Tuning:

Weber DCOE carburetors are highly tunable, allowing for precise control over the air/fuel mixture at different engine speeds and loads. This is achieved by changing the sizes of the jets, venturis, and other components.

Advantages:

- Improved airflow and reduced restriction compared to downdraft carburetors.

- Highly tunable for optimal performance.

- Can be used in multiple configurations for different engine sizes and applications.

Disadvantages:

- May not be suitable for all applications.

Overall, the Weber DCOE is a high-performance carburetor that is popular among enthusiasts and racers. Its unique design and tunability make it a great choice for those who demand the best from their engines.